Massachusetts Institute of Technology Lincoln Laboratory built two optical payloads for the United States Space Force

Image Credit: MIT-LL

Engineers and technicians at Massachusetts Institute of Technology Lincoln Laboratory in Lexington, Massachusetts built two optical payloads for the United States Space Force to be hosted on separate Japanese Quasi-Zenith Satellite System (QZSS) satellites in geostationary orbit. These payloads will support the Space Domain Awareness (SDA) mission for the United States Space Force. QZSS and the Hosted Payloads are planned to launch aboard Japan’s H3 rocket.

James Webb Space Telescope

The James Webb Space Telescope was launched on December 25, 2021, on an Ariane 5 rocket and the first images from JWST were released to the public on July 11, 2022. The telescope will allow astronomers worldwide to study every phase in the history of our Universe from the Big Bang, to the formation of solar systems capable of supporting life, to the evolution of our Solar System. The telescope is the largest ever launched into space; over 100 times more powerful than the Hubble Space Telescope.

Northrop Grumman – Unitized Pallet Structure

Flotron Dual Support Rotation Fixtures with custom payload interface tooling supported the Northrop Grumman built Forward and Aft Unitized Pallet Structure (UPS) composite assemblies. These custom Flotron fixtures included custom bottle jacks that were positioned around the perimeter of the tubular interface frames to eliminate deflection and simulate a Zero G configuration during assembly. Flotron performed a proof load and acceptance test and included both a deliverable oof load and acceptance test report in addition to a structural substantiation report.

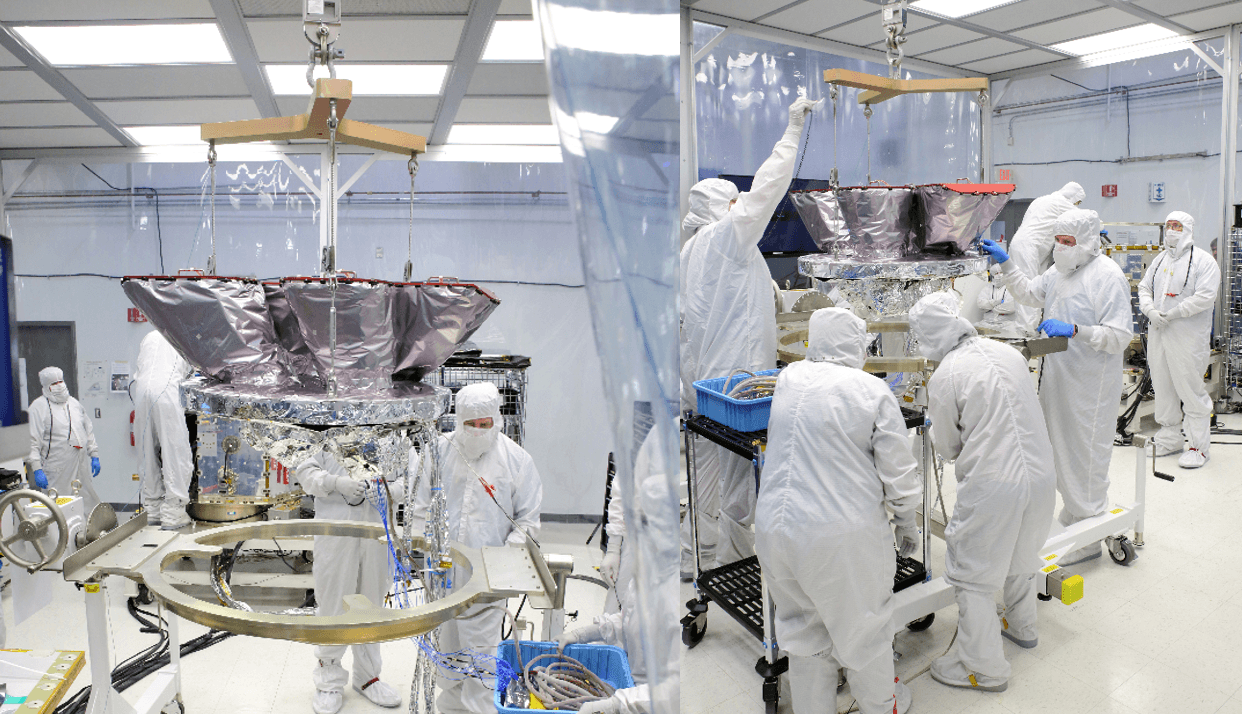

Ball Aerospace – Supporting the Beryllium mirror assemblies during testing

The Beryllium mirror assemblies were supported by a Flotron 961 Dual Support Rotation Fixture during testing at Marshall Space Flight Center. The Flotron 961 has a 4,000 lbs load rating considering SFy = 3 and SFu = 5, and a swing radius ranging from 50”-59”. Ball Aerospace’s backing structure interfaced with Flotron’s standard P15/A36 interfaces. The 900 Series’ coupling system has a stair-step resistant design that eliminates gearbox jerking during rotation of the mirrors from the 12 to 16 o’clock position, resulting in smooth motion.

Lockheed Martin – Near-infrared Camera

A Flotron 700 Series Dual Support Rotation Fixture supported Lockheed Martin’s Near Infrared Camera (NIRCam) during AI&T. This XD759 is cleanroom compatible with custom end frames, interfaces, and lubricants. The top two holes of the P8 mounting plate interfaces are slotted through vertically to maximize ergonomics of the loading and unloading process. Krytox GPL207 grease is used on the trunnion shafts, jacks, and casters. Flotron also performed a proof load test and provided a deliverable report.

Flotron’s SFP-635 Series Rotation Fixture

Flotron supported Johns Hopkins APL with cleanroom compatible SFP-635 rotation fixtures that support assembly, integration, and test activities for NASA’s Double Asteroid Redirection Test (DART) mission. The SFP-635 rotation fixture has a 335 lb load rating considering SFy = 3 and SFu = 5, electrostatic grounding features, electroless nickel plated parts, a 15° index plate can be physically pinned to the vertical upright to lockout the rotation axis, P8 mounting interfaces, and a finish option compatible in a CLASS 10K (ISO 7) clean room environments.

Learn more about Flotron’s SFP-635 Series Rotation Fixture product line.

On May 15, the primary structure for NASA’s Double Asteroid Redirection Test (DART) spacecraft returned to Johns Hopkins APL. Now equipped with its chemical propulsion system and elements of its electrical propulsion system – installed at Aerojet Rocketdyne in Redmond, Washington – the spacecraft will remain at APL through final assembly and prelaunch testing.

The DART mission is NASA’s demonstration of kinetic impactor technology, impacting an asteroid to adjust its speed and path. DART will be the first-ever space mission to demonstrate asteroid deflection by kinetic impactor.

Flotron’s 700 Series with an Electromechanical Lift

Flotron’s 700 Series Rotation Fixtures can now be ordered with an Electromechanical Lift Option with push button control that is compatible in clean room environments. A battery option is also available.

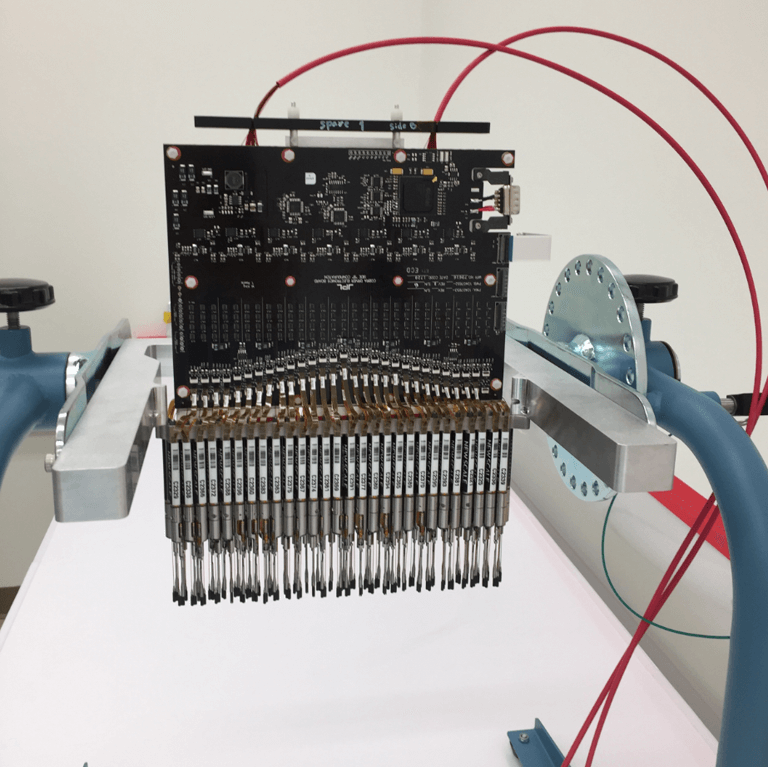

Caltech Astronomy Is Assembling & Testing the Fiber Positioning Robot Modules for the Subaru Telescope.

A module from the Subaru Prime Focus Spectrograph (PFS) at Caltech Astronomy is supported by a Flotron 202 benchtop Rotation Fixture during assembly, integration and test operations. Each module consists of (quantity 57) Ø7.7mm x 10 cm long fiber positioning robots, nicknamed “Cobra”. Each robot supports an optical fiber and functions to drive the fiber to its commanded position within a patrol region of approximately Ø9.5mm. Establishing a patrol region for each fiber eliminates the potential for tangling of the fibers. Each fiber (approximately 65 meters in length) is a conduit of light collected at the focal plane and delivered to the spectrographs located in a room next to the telescope. The finished spectrograph system will incorporate 42 of these modules (laid out in a hexagonal shape) and contain 2,394 fiber positioners capable of simultaneous observation of up to 2,394 targets at one time, a technology breakthrough.

Flotron’s 202 Benchtop Rotation Fixture has a 130 lbs load rating considering SFy = 2 and SFu = 3. Trunnion lock knobs on the end frame bearing housings eliminate backlash in the system. Additionally, a 15° index plate can be physically pinned to the vertical upright to lockout the rotation axis. Standard interfaces include either mounting plates or angle mounts. The standard finish option is compatible in a CLASS 10K clean room environment. The end frames are powder coated Flotron blue and the gearbox is wet painted Flotron blue. All of the moving parts and hardware are zinc plated. An ESD ground lug can be utilized for compatibility in electro-statically protected areas. Learn more about Flotron’s 200 Series Benchtop Rotation Fixture product line.

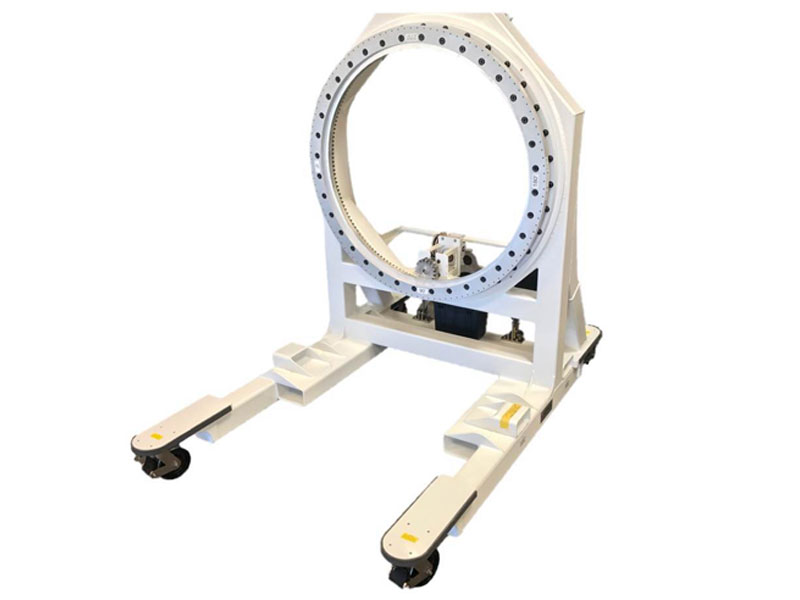

Cantilevered Satellite Integration Fixture

There are cases where spacecraft integration requires an access hole thru the payload mounting interface. This access may be required for instrument integration, propulsion integration, spacecraft wiring … etc. To provide a scale of the size of the Flotron represented in the image below, the available payload swing diameter (as measured from the rotation centerline) is Ø110″ and the ID of the slew ring is approximately Ø54″. This cantilevered satellite integration fixture can support high moment and radial loads considering SFy = 3 and SFu = 5 in addition to a simultaneous (horizontal and vertical) dynamic loading condition. The resultant stability (with payload integrated) is 0.75G. The payload can be rotated 360° either by hand crank or by interfacing with a socket and electric hand drill. The gear drive is self-locking and non-back-driving with minimal backlash and the index plate on the input shaft can be physically pinned. The payload mounting interface dimensions and tolerances were specified by our customer.

The finishes are compatible in a CLASS 10K clean room spacecraft manufacturing environment (no zinc, tin, or cadmium) and the lubricants were selected for compatibility. Covers were added over the geared slew ring and pinion gear to eliminate pinch points and to mitigate lubricant migration. The operator can maneuver the Rotation Fixture by the push bar or the tow bar. Forklift tube pockets have been incorporated at the rear to lift the Flotron (with the payload integrated) as well as at the side to handle the empty Flotron. The caster wheel material and geometry were specified to optimize rollability. Additional features include leg bumpers, relevant caution labels, angular indicator labels, and a storage container. Flotron fabricated a 2X proof load test simulator that represents 200% payload weight, 200% resultant moment and 100% torque. Flotron performed a proof load test with the payload simulator integrated when supported by the casters as wells as when lifted with a forklift. Weld inspection of critical welds (as defined by Flotron Engineering) was performed using an Eddy Current inspection method through the powder coat finish.

Customer Review:

The spacecraft mated to the Flotron fixture, all features were exercised to the delight of our customer and it is working excellent! Thank you again for the fine craftsmanship that your team delivered on.

Planetary Resources’ Arkyd-6 Spacecraft Is Assembled & Tested

Planetary Resources’ Arkyd-6 Spacecraft is assembled and tested on a Flotron 212 Benchtop Rotation Fixture and then inspected in the cleanroom at the Redmond Washington facility. Arkyd 6 will test systems that will be used in the Arkyd 200 asteroid exploration mission with a target launch date of 2020. The first target asteroid resource will be water, which can be split into hydrogen and oxygen using solar energy and used as a fuel source for spacecraft. Luxembourg recently offered a legal and regulatory framework relating to the authorization, supervision, ownership and utilization of valuable space resources identified and extracted on celestial bodies by private operators.

Flotron’s 212 Benchtop Rotation Fixture has a 130 lbs load rating considering SFy = 2 and SFu = 3. The gearbox is self-locking and non-back-driving and is sealed and pressure tested. Trunnion lock knobs on the end frame bearing housings eliminate backlash in the system. Additionally, a 15° index plate can be physically pinned to the vertical upright to lockout the rotation axis. Standard interfaces include either mounting plates or angle mounts. The “C” finish option is compatible in a CLASS 1K clean room environment. The end frames are powder coated gloss white and the gearbox is wet painted gloss white. All of the moving parts and hardware are either electro-less nickel plated or stainless steel. The lubricant in the trunnion bearings is Krytox-GPL207, however can be replaced with Braycote 601EF or other customer approved option. An ESD ground lug can be utilized for compatibility in electro-statically protected areas. Learn more about Flotron’s 200 Series Benchtop Rotation Fixture product line.

SDL Performing Payload I&T Activities for the ICON Observatory

Space Dynamics Laboratory (SDL) performing payload integration & test activities for the ICON Observatory Spacecraft using a Flotron Rotation Fixture. ICON is scheduled to launch 12/08/2017. ICON will explore how both earth weather and space weather in the ionosphere affect global positioning satellites and radio communications. As of 10/16, the solar arrays are stowed and pre-ship testing is almost complete. Orbital ATK is preparing for integration with the Pegasus launch vehicle at Vandenberg AFB towards the end of October.

An off-the-shelf 700 series Rotation Fixture is shown below supporting the integration activities and provides adequate swing clearance without sacrificing ergonomic operating height. The rating of this Engineered solution considers the appropriate dynamic loading condition and safety factors. The Flotron is compatible in an ISO 6, CLASS 1K clean room environment. All of the moving parts and hardware are either electro-less nickel plated or stainless steel. The end frames are finished with gloss white powder coat. Compatible lubricants have been specified. The gearbox is sealed and pressure tested. Leveling jacks have been incorporated to level the Flotron on uneven floors and help to stabilize the fixture. The caster wheels were selected to maximize rollability while considering payload sensitivity during transport. Learn more about Flotron’s 700 series rotation fixtures.

NASA’s Transiting Exoplanet Survey Satellite (TESS) Camera System

TESS will perform a two year survey of the 200,000 brightest stars in the sky to monitor changes in brightness caused by planetary transits occurring outside of our solar system. The goal being to identify smaller planets orbiting bright stars, good candidates for new earths and super earths, which can be further characterized along with their atmospheres. MIT Lincoln Labs is providing the Four Wide Field-of-View (24° x 24°) CCD Cameras, Orbital ATK builds and operates the LEOStar-2 spacecraft, NASA GSFC is providing project management, systems engineering and safety/mission assurance and the TESS Spacecraft will be launched into high earth orbit (HEO) on a SpaceX Falcon 9 Full Thrust rocket.

Flotron 700 Series Rotation Fixture:

An off-the-shelf 700 series Rotation Fixture is shown below supporting the integration activities and provides adequate swing clearance without sacrificing ergonomic operating height. This rating of this Engineered solution considers the appropriate dynamic loading condition and safety factors. The Flotron is compatible in an ISO 6, CLASS 1K clean room environment. All of the moving parts and hardware are either electro-less nickel plated or stainless steel. The end frames are finished with gloss white powder coat. Compatible lubricants have been specified. The gearbox is sealed and pressure tested. Leveling jacks have been incorporated to level the Flotron on uneven floors and help to stabilize the fixture. The caster wheels were selected to maximize rollability while considering payload sensitivity during transport. Additional details about Flotron’s 700 Series Rotation Fixtures can be found at www.flotron.com/products/700-series.

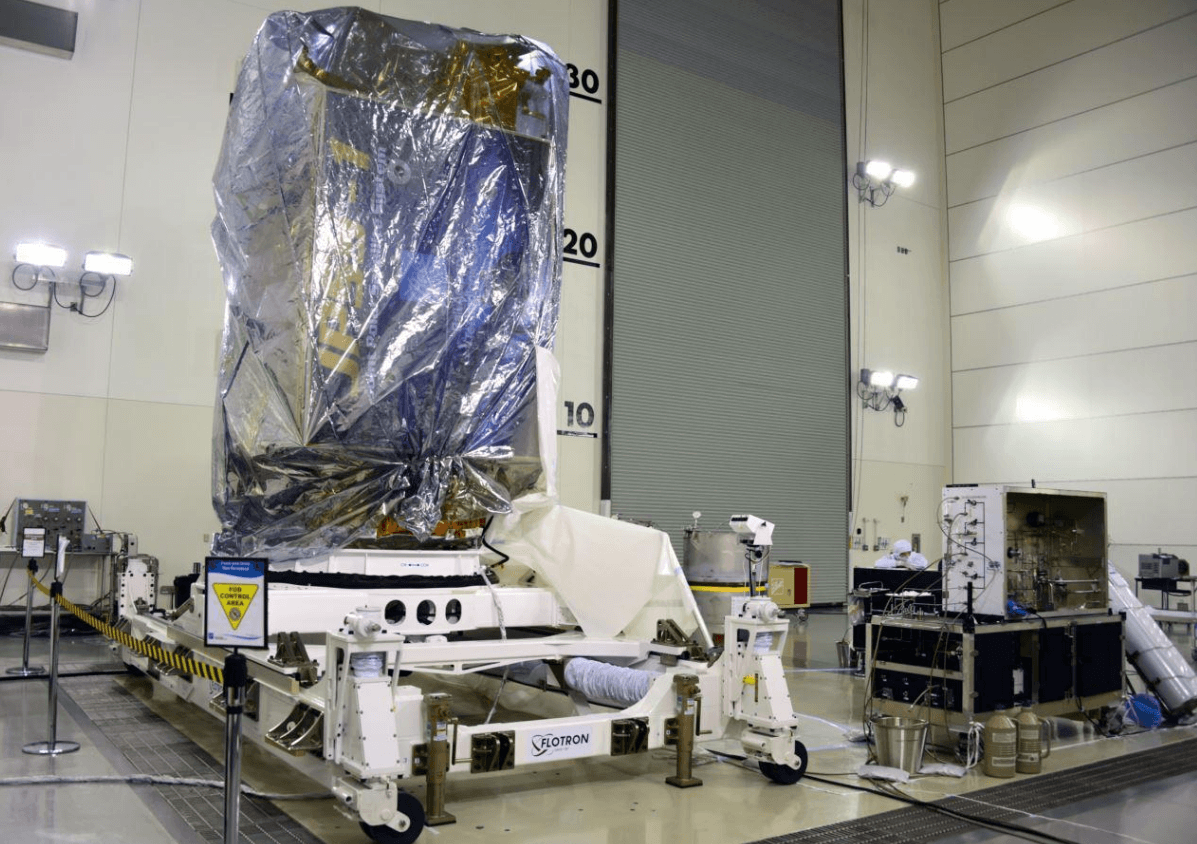

Flotron Mid-Size Satellite Positioner Supporting JPSS-1 at Vandenberg AFB

The NASA/NOAA JPSS-1 Satellite designed and built by Ball Aerospace Begins Final Preflight Processing at Vandenberg AFB. The global data from Joint Polar Satellite System (JPSS) will be used in numerical weather prediction models to help forecast extreme weather events and improve public warnings. The satellite was assembled, transported to the launch site and then upended to the vertical orientation using a Flotron Satellite Positioner where it will be prepared for launch and integrated with the ULA Delta II launch vehicle.

Flotron Design Considerations:

Flotron’s Mid-Size Satellite Positioner is designed to minimize risk to high value hardware by keeping the Space Vehicle (SV) on the same tool throughout processing activities. The SV can be lifted with an overhead and mounted to the Flotron interface in the vertical orientation, tilted down to provide technicians ergonomic access to all sides during integration and test activities, transported in this orientation through the facility to the shipping container via the tow bar and wheeled casters where it is loaded into the shipping container and transported by truck or air to the launch site. At which point, the Flotron with SV can be unloaded from the shipping container, rolled into the high bay, tilted vertically for final preflight processing and integrated with the launch vehicle. The overhung moment capacity of this Flotron Satellite Positioner is on the order of 750,000 in-lbs considering appropriate dynamic load factors and safety factors.