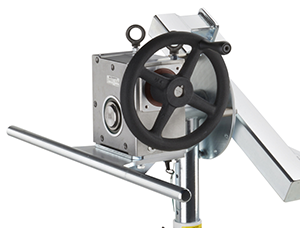

Continuous improvement of ergonomics and safety in the work environment are the goals Flotron shares with our customers. A push bar can help to more ergonomically maneuver the Rotation Fixture around a customer facility. The combination of having swivel locks engaged on the rear casters and a handle to grab for leverage can make a world of difference during transportation.

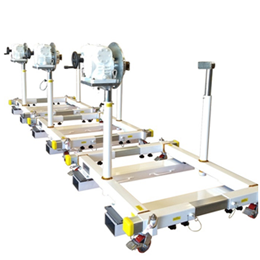

We have had many requests for features that ease lifting and transportation of our larger Rotation Fixtures. In addition to our tow bar option, Flotron also offers forklift tubes. Forklift tubes provide a safe pocket location for a forklift to handle the Flotron fixture while minimizing potential concerns about stress caused by fixture deflection. These forklift tubes also help alleviate concerns of tip over by providing a stable lift point. Flotron personnel can help to advise if your lifting application is safe for the rotation fixture.

One of the special options Flotron offers for our Rotation Fixtures is a tow bar. The tow bar can be stowed up at near a 90 degree angle to the floor. By simply removing a clip, the tow bar can be lowered for attachment to a towing vehicle. If special tow bar requirements exist, Flotron can modify our existing tow bar designs to meet them.

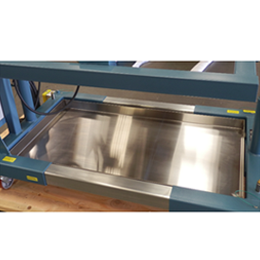

Sometimes customer payloads have the tendency to leak fluid in certain orientations and/or processes. Intentionally capturing and containing these fluids with our dip pans can prevent contamination, undesired contact with hazardous materials, or a slippery working surface.

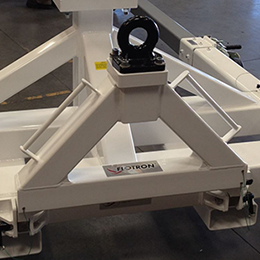

Many Flotron fixtures with our standard finish have been successfully used in FS209E class 10,000 (ISO class 7) clean rooms. When specific customer Materials & Process requirements diverge from our standard finish option, we do have the capability to offer a modified standard solution. Common clean room related requests include our gloss white powder coat finish, substitution of electro-less nickel plated and stainless steel components for zinc plated and black oxide ones, and the use of clean room compatible lubricants like Krytox or Braycote.

Rolling surfaces and stability criteria vary between our customers and we have made an attempt to accommodate most customer needs with our standard off-the-shelf casters listed in our catalog and on our website. Some of our customers’ needs cannot be fulfilled with the standard casters and in these cases we would be happy to help identify a caster that is more suitable. We can provide casters with crowned geometries and harder wheel materials to maneuver heavy fixtures and payloads with less operator input, however this will increase rolling vibration transmitted to the customer’s payload when rolled over uneven surfaces. We can also offer dual-wheel or single wheel (foam-filled) pneumatic tire casters or spring loaded casters to roll over uneven terrain and maintain stability. We can also offer v-groove wheel casters to roll on a track system or high temperature casters that can sustain extreme thermal environments.