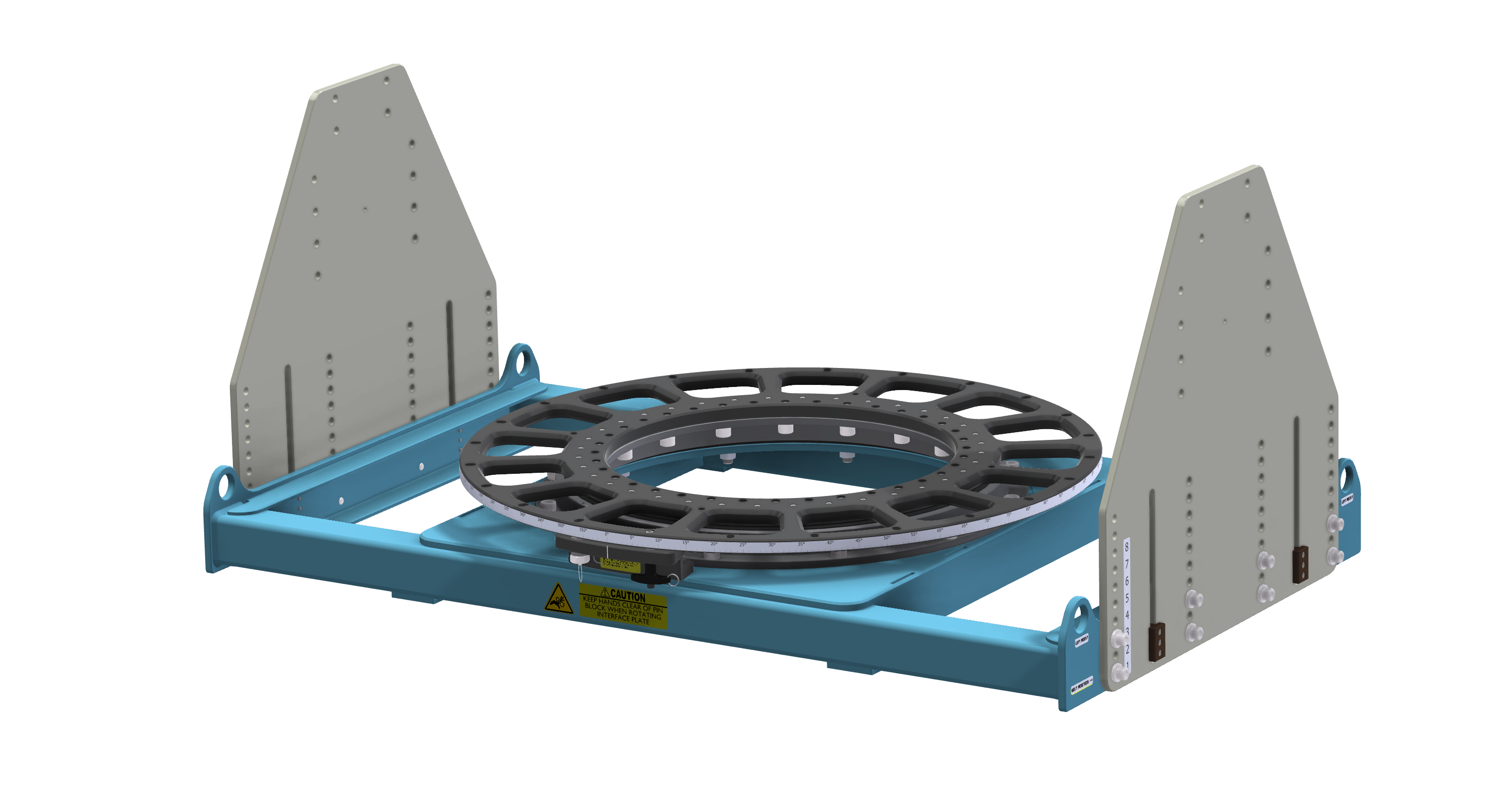

Flotron Rotation Fixture supporting six beryllium mirror segments for NASA JWST.

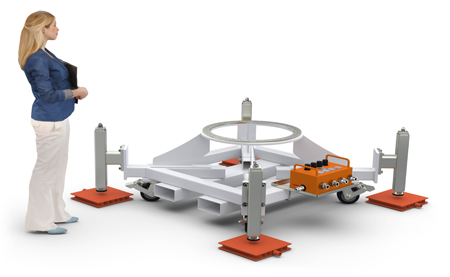

Flotron Satellite Positioner transports BATC designed, manufactured & tested JPSS-1 NASA/NOAA next generation Weather Satellite to the launch site at Vandenberg AFB.

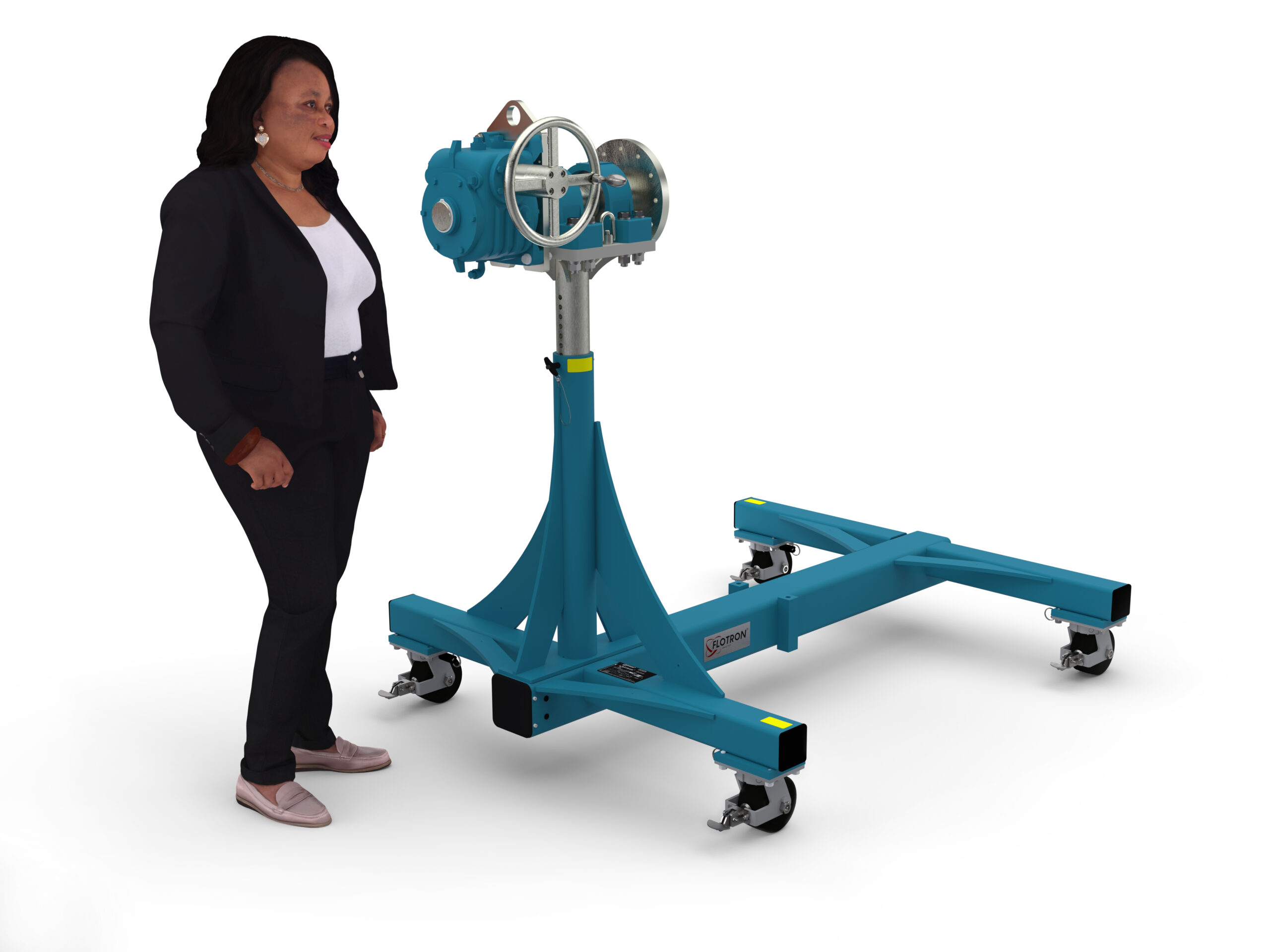

Flotron designed and manufactured a mid-sized Spacecraft Positioner.

Flotron designed and manufactured assembly & test workstations to support two large JWST composite structures.

Flotron designed and manufactured Assembly, Integration & Test Workstations to support NASA's CYGNSS Program.